Waste Battery

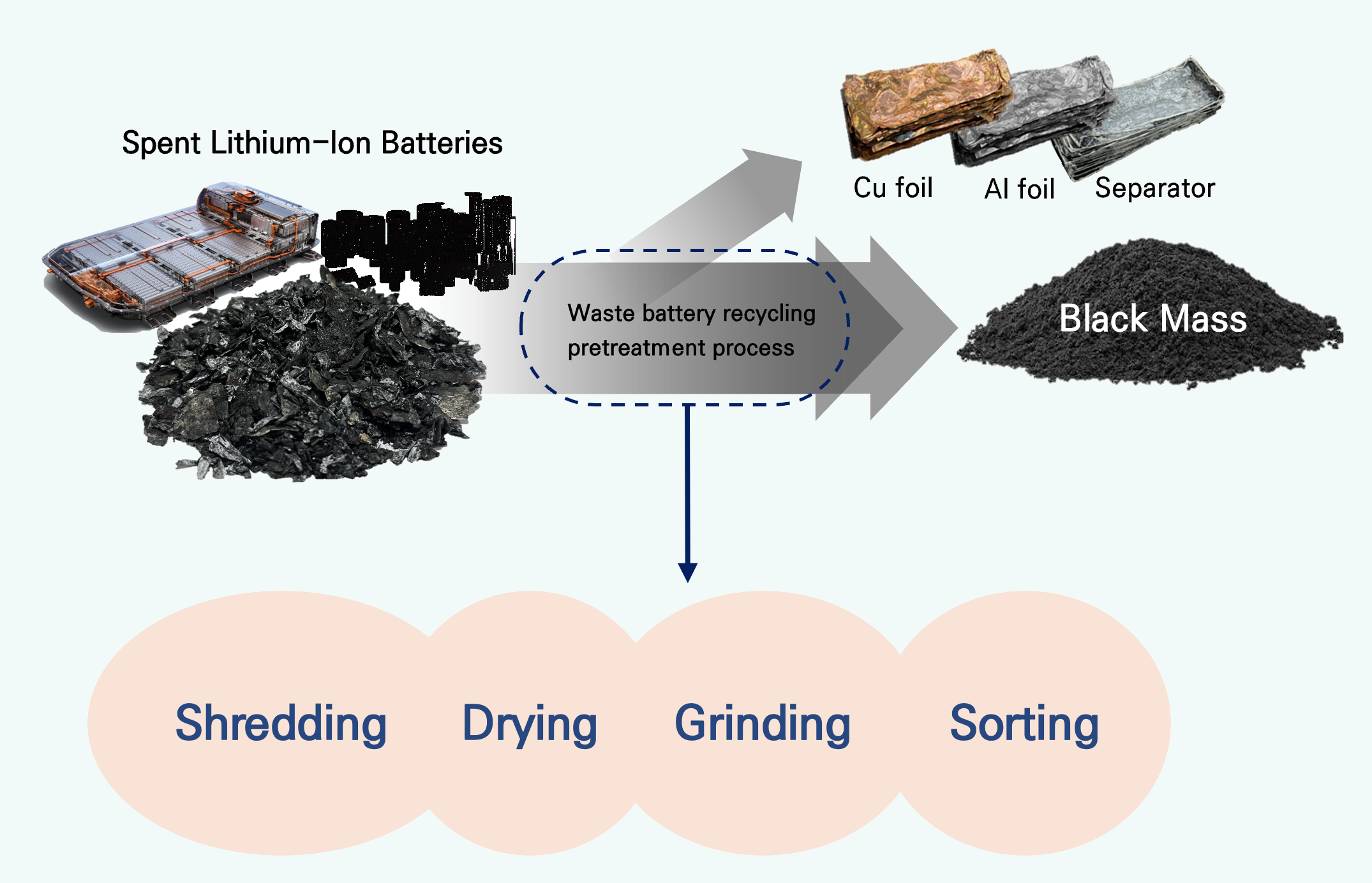

Waste battery recycling pretreatment process

Collecting black mass in which valuable metals such as Ni, Co, and Mn are concentrated from waste batteries (NCM series waste secondary batteries, scrap, etc.) through processes such as shredding, and grinding, drying and sorting.

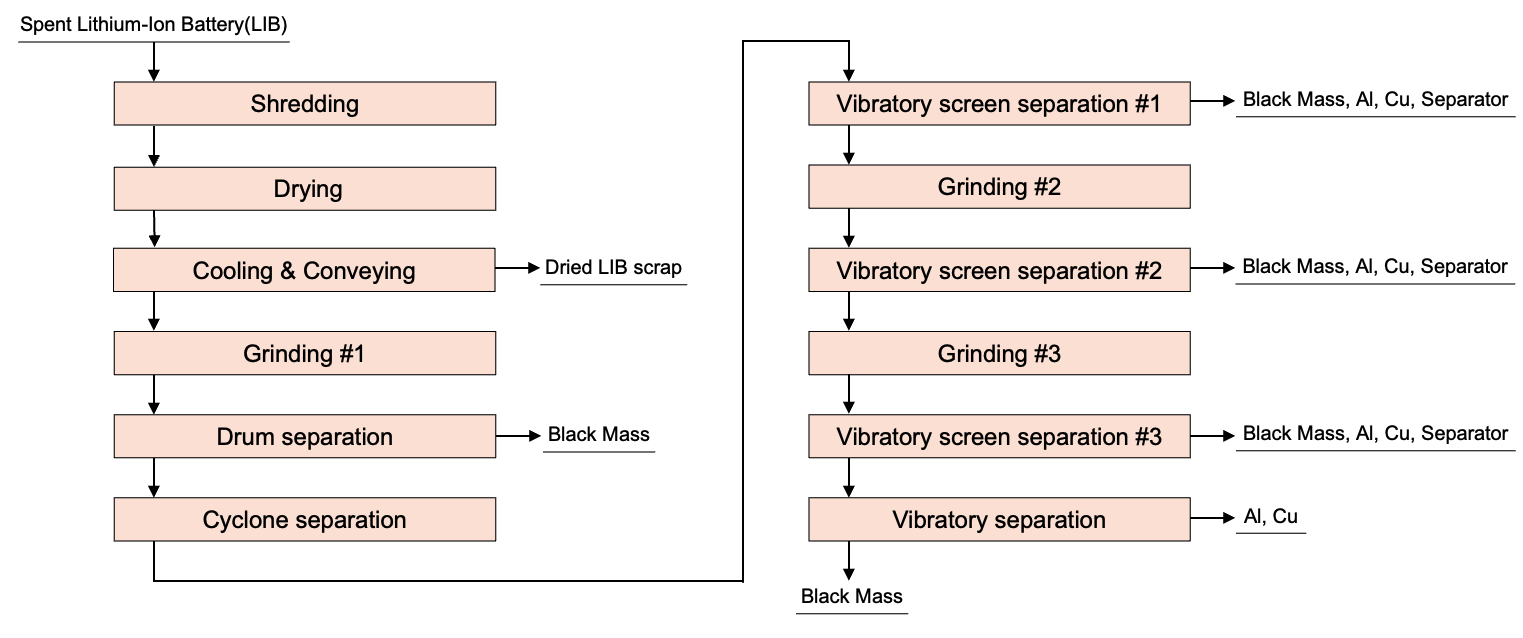

DJ MEX's waste battery pretreatment process largely consists of the ‘shredding-drying’ process and the ‘grinding-sorting’process.

A recycling process is being operated at a plant measuring approximately 400 pyeong in the Chungju High-Tech Industrial Complex.